Lifting slings are commonly used in various industries for the safe and easy lifting of heavy and large dimension loads. The lifting of heavy weights is a dangerous process, therefore we tend to see accidents that occur on construction and cargo loading sites, resulting in serious injury, death or damage to company assets. The hazards and risks are usually due to the inappropriate use of slings, the underestimation of the specific lifting operation (or cargo specifications) and the poor choice of slings.

The importance of appropriate lifting slings

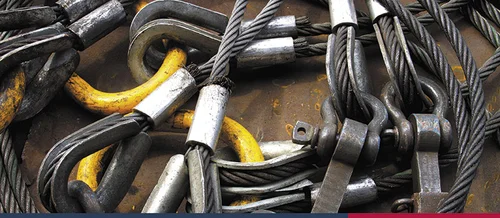

Slings are one of the most important parts in lifting heavy objects. The successful use of such equipment is largely determined by the proper selection and use in accordance with the prescribed technical regulations, taking into account the permissible loads and other vital parameters. There are three types of slings that are commonly used: chain, textile and wire rope slings. When choosing slings, it is important to evaluate size, weight and shape of a cargo, as well as how the slings are going to be used and attached. All these aspects must be weighed when choosing slings so that they can withstand the intended lifting load, have the appropriate length and the required number of loops.

Slings are one of the most important parts in lifting heavy objects. The successful use of such equipment is largely determined by the proper selection and use in accordance with the prescribed technical regulations, taking into account the permissible loads and other vital parameters. There are three types of slings that are commonly used: chain, textile and wire rope slings. When choosing slings, it is important to evaluate size, weight and shape of a cargo, as well as how the slings are going to be used and attached. All these aspects must be weighed when choosing slings so that they can withstand the intended lifting load, have the appropriate length and the required number of loops.

In all cases, it is important to make sure that the legs of slings would not be overloaded and that the lifting weight is stable during the whole lifting process. There are cases when lifting loads are calculated correctly, but the legs get congested during lifting due to the change of the gravity center. Therefore, it is important to evaluate not only the physical aspects of the cargo, but also probabilities of potential risks. It is also very important that all accessories and fasteners would match the parameters of an exact cargo, but this usually requires the lifting know-how.

The most common mistakes

In practice, mistakes are inevitable. This applies to all industries, but especially lifting. Unfortunately, some lifting flaws are recurring and lead to accidents. Knowing what are the common mistakes in sling selection makes it easier to protect yourself and prepare without any stress. To understand whether the sling fully meets your needs, you have make sure that:

● You have a valid sling manufacturer certificate

● You have a valid sling manufacturer certificate

● You have a manufacturer's instruction manual

● Load of the cargo corresponds to the permissible limit load of the sling

● The type and construction of the sling is suitable for the intended load and its specifics

● The load is attached properly, according to the instructions

● You know all the important information about the load (weight, center of gravity position, probability of gravity center displacement, attachment points)

● You understand all the conditions of lifting the load and have assessed the circumstances and potential risks

When choosing a lifting sling, it is also important to use all the necessary accessories, which provide more safety, facilitate lifting tasks and additionally protect the cargo or the sling from any possible damage and breakage. In any case, it is important to avoid improvisation and consult with certified lifting professionals beforehand. Not only will it give your employees more security, but you will also protect yourself from financial losses. With Certex lifting slings your work will become hassle-free and you will certainly reach a much better efficiency for any of your lifting tasks!