Optimal space utilization

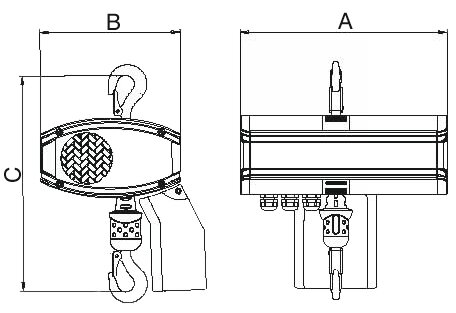

Compact dimensions and best hook approach, space saving trolleys.

High safety in operation

Emergency Stop button, 48 V contactor control, drop stops, robust industrial design.

Gentle work

Upper and lower lifting limit switch, minor noise emission, stepless load moving with motor trolley and inverter.

Low installation and maintenance costs

Standardized electrical modules in general with plug connections, easy accessibility due to modular construction, low weight.

Advantage: Efficient and economical operations with the highest quality

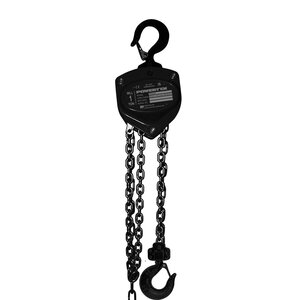

Standard equipment:

- Upper hook

- 2 lifting speeds up to 6/1 ratio depending on load

- Up to 5.000 kg, 2.500 kg in a single fall

- Chain sprocket with intermediate teeth and metal chain guide

- Mechanical overload device

- 2-step upper and lower emergency lifting limit switch

- High-quality reliable contactor control 48V with main switch

- Electrical connections plugable, for relieved maintenance

- Thermal protection for lifting motor

- Control pendant IP65 with emergency button, with plug

- Lifetime brake

- Separate brake rectifier

- Electrical provision for motor trolley

- Housing made completely from aluminum

- Protection IP55

- Ambient temperature -20°C up to +50°C

- Epoxy powder painting, 70 µm

Options:

- Trolley limit switch

- Upper eye suspension instead of hook

- Load chain and hook made from stainless steel

- 2 step and 4-step gear limit switches

- Second hoisting brake

- Manual brake release

- Rain cover

- Standby heating for motors and electrics

- Remote radio control „RadioMaster“

- Explosion-proof application

- Power supply from 230V up to 675V, 3 phases

- HandyMaster control pendant for increased efficiency

- Version for the food industry

- CraneKit version

Electric Chain Hoist CHAINster

Optimal space utilization

Compact dimensions and best hook approach, space saving trolleys.

High safety in operation

Emergency Stop button, 48 V contactor control, drop stops, robust industrial design.

Gentle work

Upper and lower lifting limit switch, minor noise emission, steple

excl. VAT

Part code: